Now offering the most reliable and accurate label applicator in the world.

BenchMAX

Fully Optioned

Our fastest and most flexible bottle label applicator, it labels all container diameters larger than 8 mm (3/8 inch). Suits businesses that label from 150,000 up to 1,000,000+ containers per year.

BenchDELUXE

Hands-free

Labels faster and improves productivity by reducing double handling by at least 3 x. For example, one operator can label, box and pallet up to 1,000,000 bottles of wine a year.

BenchMARK

Entry Level Electric

Will suit businesses that label from 10,000 up to 250,000+ containers per year. Labels any bottle, jar, can or round container with a diameter larger than 55mm (2 1/8 inch)

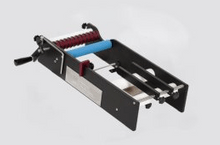

BenchMATE

Hand Operated

Perfect for start-up’s & boutique manufacturers labelling bottles, jars, vials or any tubular containers with diameters larger than 18mm (3/4 inch) or larger than 55mm (2 1/8 inch).

Introducing the Bench Series

Efficient

Fast and reliable, our applicators will label your packaging in seconds – 23 bottles/min

Durable

Australian crafted, 100% customer satisfaction guarantee

Dependable

Legendary trouble-free performance; 5-year warranty on non-consumable parts

Accurate

Precise label placement, proprietary technology to ensure best in-class accuracy

Eastern Canada’s official retailer for Great Engineering’s top of the line, Australian crafted label applicators.

Manual and electric models, suitable for labeling anything sold in bottles, cans, jars, vials or any cylindrical container. Great Engineering’s bottle labelling machines are used by world leading brands like Chivas Regal, Aesop, Carlton United Breweries, Schwarzkopf & many others, who value trouble-free reliability and precise label placement from a label applicator. Applications: Bottle Labeling, Can Labeling, Vial Labeling Machine, Jar Labelling Machine, Tube Labelling Machine.

Industry Videos

Beer and Cider

Cosmetics

Wine

Spirits

Get a Quote on the Most Reliable Bottle Labeller in the World.

With more than 26 years in the label business, Great Engineering has worked with thousands of brands worldwide, surveyed them all and everyone has stressed how down time caused by label jams & substandard finishes are among the most costly and likely failures in their production process. Great Engineering has designed superbly engineered machines to minimize waste of time and materials on every level! And it’s the fact that they deliver on all the finer points that matter and make their customer’s life’s easier when labeling thousands of products, day in day out, that the true value of their machines becomes apparent.